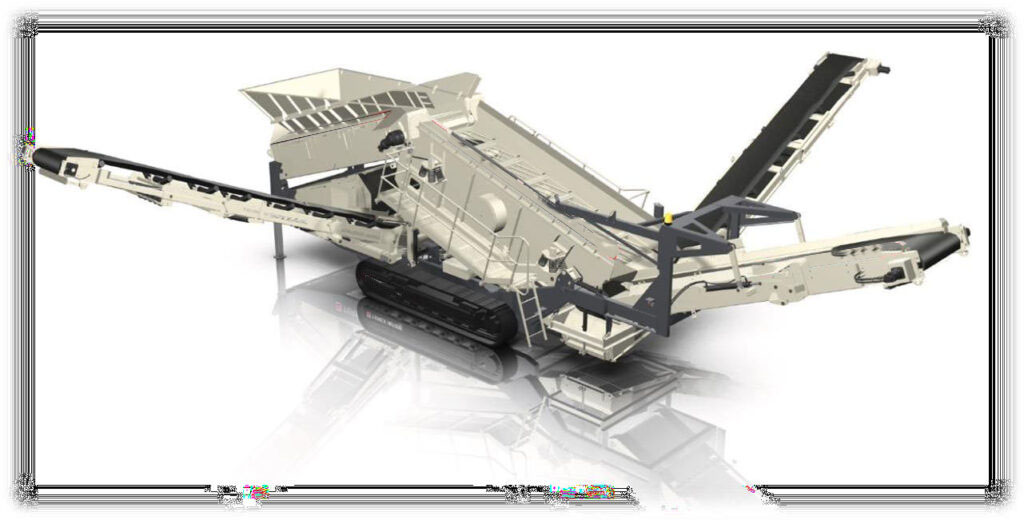

Product Specification

The excellent design of the crawler mobile heavy-duty screening equipment makes it easy to use in independent screening simple process and high throughput in stand-alone screening operations.

The large material belt conveyor with increased stacking height supports combined operation with The large material belt with increased stacking height supports combined operation with lower stage equipment (impact crusher, jaw crusher, cone crusher, finisher screen) to meet the user’s different production line process requirements. Proven technology combined with extensive application experience means it always works well, no matter what the application.

| Hopper Volume | 7m3 |

| Maximum Feed Size | 500mm |

| Maximum Throughput | 500tph |

| Engine | CAT C4.4 96.5KW |

| Screen Box | 2 Layers Of Screen Box (4.8m*1.5m) |

| Large Material Belt | Bandwidth 1200mm, discharge height 3.6m |

| Medium Material Belt | Bandwidth 800mm, discharge height 3.2m |

| Fine Material Belt | Bandwidth 800mm, discharge height 3.6m |

| Transport State Size | 14.7m*3.0m*3.4m |

| Working State Size | 14.9m*15.7m*4.5m |

| Weight | 3200kg |

The power of the whole machine comes from the onboard Caterpillar diesel engine, which is not restricted by electricity, and has strong, stable and reliable power.

Production Process

The raw material enters from the feeder and is transported to the top drying box by the chain conveyor for screening, and the screened large material is output from the large material conveyor belt. The remaining two sizes of materials fall into the bottom screen box for screening, and then output from the middle material conveyor belt and the fine material conveyor belt respectively.

Sieve Plates And Screens

1. Grate Screen (top)

Structure: Made of high-strength wear-resistant steel (>400HB).

Features: able to withstand the impact of super large material feeding.

Application: primary screening, heavy-duty working conditions, high impact strength of materials.

2. Needle Sieve (top)

Structure: Larger diameter needle-like rods made of spring steel.

Features: It can withstand the impact of super-large material feeding, and produces secondary vibration when impacted, which is beneficial to decompose entangled materials; its structure makes it easy to sieve slender materials.

Application: primary screening, heavy-duty working conditions, high impact strength of materials, low screening accuracy requirements.

3. Polyurethane Sieve Plate (top)

Structure: It is molded from polyurethane, and can be processed into hexagonal, circular, rectangular and other mesh shapes to suit different materials.

Features: strong wear resistance and long service life, which are 3-5 times that of steel sieve plates and 5 times that of ordinary rubber sieve plates; light weight, small friction coefficient, which is conducive to material sliding and sieving.

Application: materials with strong wear resistance, washed with water.

4. Perforated Sieve Plate (top)

Structure: Made of ordinary steel, stainless steel, other wear-resistant metals, rubber, etc., can process hexagonal, circular, square, rectangular and other sieve shapes to suit different materials, and the sieve hole diameter can be selected in a wide range .

Features: It can withstand heavy loads, and ordinary sieves cannot sieve super-large materials.

Application: primary screening, heavy-duty working conditions, high impact strength of materials.

5. Ordinary Woven Wire Mesh (top or bottom)

Structure: longitudinal and transverse wires are interwoven one above the other at right angles to form a screen with square holes; the wires of such screens can be made of high tensile steel or stainless steel.

Features: high porosity, low cost, most widely used.

Application: Precision screening of various dry materials.

6. Finger Sieve (bottom)

Structure: Cylindrical rods of large diameter made of spring steel inserted in a polyester amine base.

Features: It can withstand the impact of super-large material feeding, and produces secondary vibration when impacted, which is beneficial to decompose the entangled material; its structure makes it easy to sieve the slender material.

Application: Primary screening, heavy-duty working conditions, high impact strength of materials; low screening accuracy requirements.

7. Self-Cleaning Mesh (bottom)

Structure: Arrange wavy metal wires and straight metal wires at intervals in the longitudinal direction, or all wavy metal wires, and use metal wires to fix at intervals in the horizontal direction to maintain the screen structure.

Features: When the screen box vibrates, the wavy metal wire on the screen continues to generate secondary vibrations, which helps to reduce material jams.

Application: wet materials with high moisture content.

8. String Screen (bottom)

Structure: Longitudinally arranged high-strength metal wires tensioned according to the set tension.

Features: When the screen box vibrates, the metal wire on the screen continuously generates secondary vibrations to achieve self-cleaning effect.

Application: viscous materials, wet materials, and fine materials with a particle size below 10mm.

Use Case Scenario